Dongguan Weisite Intelligent Technology Co., Ltd.

Mr. Yuan 18851191830

Company Tel: 0769-2288 8508

Company email: weiq.sales@weste-group.com

Online QQ: 2251002748

Company Address: No. 4, West Street, Zhenyuan Road, Wusha Caiwu Industrial Zone, Chang'an Town, Dongguan City

Analysis of Common Methods of Auto Lamp Air Leak Detector

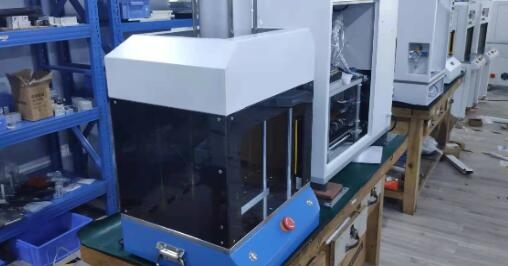

Airtight Leak DetectorIt is used to ensure products in the manufacturing process of car lightsImportant test equipment whose tightness can meet the standard. As an important part of vehicle accessories, car lights play a protective role in car lighting, driving signals, steering, etc. during car driving. However, since the design, manufacture and assembly of car lights will inevitably cause leakage problems due to insufficient air tightness, the use of air tightness leak detectors is particularly important. So what are the commonly used methods when designing and manufacturing car light air tightness leak detectors?

The air-tightness testing methods commonly used in the design of car light air-tightness leak detectors mainly include positive and negative pressure testing, component analysis, ultrasonic testing, optical testing, and air pressure testing. The design principles are also different. For example, the working principle of the air tightness leak detector adopting the negative pressure test method is to put the tested lamp workpiece into the tester, by evacuating the tester into a vacuum, and then maintaining the pressure for a certain period of time, as long as the specified time The pressure drop in the leak detector is within the specified range, and the air tightness of the tested workpiece is deemed qualified. Because the negative pressure test is sometimes distorted and the detection accuracy is not high, the usage rate in the air tightness detection process of the car lights is not high.

Component analysis method is another detection method used in the design and manufacturing process of car lamp air tightness leak detector. Its working principle is to fill the interior of the car lamp with detection gases of different air, and when the air pressure inside the car lamp When a certain value is reached, the component analyzer of the air-tightness leak detector is used to detect the surface of the lamp. Once there is a leakage gap, the gas component analyzer will automatically display the distribution unit of the leaking gas, which can quickly Determine the tightness of the lights and find out the specific location of the leak.

The optical detection method refers to mixing a certain gas into the car lamp through an airtight leak detector, and quickly analyzes and judges the sealing condition of the car lamp according to the deviation and the angle of the light projection phase in the car lamp. Although it is more intuitive, the efficiency is not high, and the error is relatively large, so the utilization rate is not high.

The rationality of the method when designing the lamp air tightness leak detector will directly affect the detection efficiency and the accuracy of the detection results to a certain extent. Once the test results of the lamp air tightness leak detector show a large error, it may cause the lamp to be fogged due to insufficient air tightness during use, and the pressure in the lampshade will change excessively or the lamp inner product will appear. Water and other issues affect the service life of car lights.

Dongguan Weisite Intelligent Technology Co., Ltd. integrates the design, production, sales and service of air tightness testers, audio testers and other non-standard automation equipment