Dongguan Weisite Intelligent Technology Co., Ltd.

Mr. Yuan 18851191830

Company Tel: 0769-2288 8508

Company email: weiq.sales@weste-group.com

Online QQ: 2251002748

Company Address: No. 4, West Street, Zhenyuan Road, Wusha Caiwu Industrial Zone, Chang'an Town, Dongguan City

How to optimize the air tightness tester

The use of airtight devices is becoming more and more common in modern industrial production,Air tightness testerThe use of is an important means to ensure the stability of the performance of the sealing device, and the stability of the performance of the seal is also an important link to ensure the quality of the product and the safety of production and life. There are many leak detection methods available for the air tightness tester. The commonly used methods include bubble detection, smearing, gas flow testing, tracer gas leak detection, ultrasonic testing, and pressure change testing. Among them, the pressure change test method is one of the most frequently used air tightness testers in the manufacturing process in recent years. Its advantage is that the pressure test method can eliminate the influence of some external environmental factors through the pressure test method, and make the test results more accurate. . However, compared with the international level, the differential pressure air tightness tester designed and manufactured in my country has a certain gap in detection accuracy and test efficiency, so related optimization work becomes very important.

To shorten the gap between the technical level of my country's differential pressure air tightness tester and other developed countries, it is necessary to optimize not only the design of the detection system, but also the online measurement, temperature compensation, and instrument portability. If you want to optimize the influence of factors such as gas pressure and temperature changes during the test on the accuracy of the test results, it is necessary to establish a more complete mathematical model of the inflation process and the differential pressure detection process based on the theory of gas thermodynamics. To solve the problem of the efficiency and accuracy of the online automatic measurement of the air tightness tester, the process of designing the instrument must be studied on the gas dynamics and energy conservation equations, and through multiple measurements to ensure the error range of the online automatic measurement data Must not exceed 2.5%.

In the design process of the air tightness tester, through scientific and reasonable theoretical research, combined with repeated test data, an effective temperature compensation scheme is designed to reduce the influence of temperature changes on the accuracy of the test results. After the program design process is completed, the optimization of the airtightness tester design program can be truly realized through repeated leak rate detection experiments and accuracy calculations.

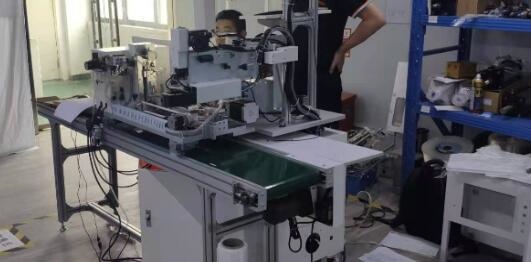

Dongguan Weisite Intelligent Technology Co., Ltd. integrates the design, production, sales and service of air tightness testers, audio testers and other non-standard automation equipment